When working with natural gas compression and similar equipment, it is inevitable to produce methane emissions. In addition, the growing production and utilization of natural gas in Canada has undoubtedly increased methane production.

What Exactly Is Methane?

Methane is a colourless, highly flammable gas. The primary usage of methane gas is everything we need that requires natural gas; this includes cooking and heating. For industrial companies, it is used to produce plastic, fertilizers and more.

Consequently, methane is a primary contributor to hazardous air pollutants and potent greenhouse gases. Greenhouse gases trap and hold the heat in the atmosphere, which warms the Earth's surface. You may also know this as Global Warming. That said, natural gas burns much cleaner as long as it's contained. That means fewer harmful emissions overall than diesel or gasoline.

Cleaner Natural Gas Conversions

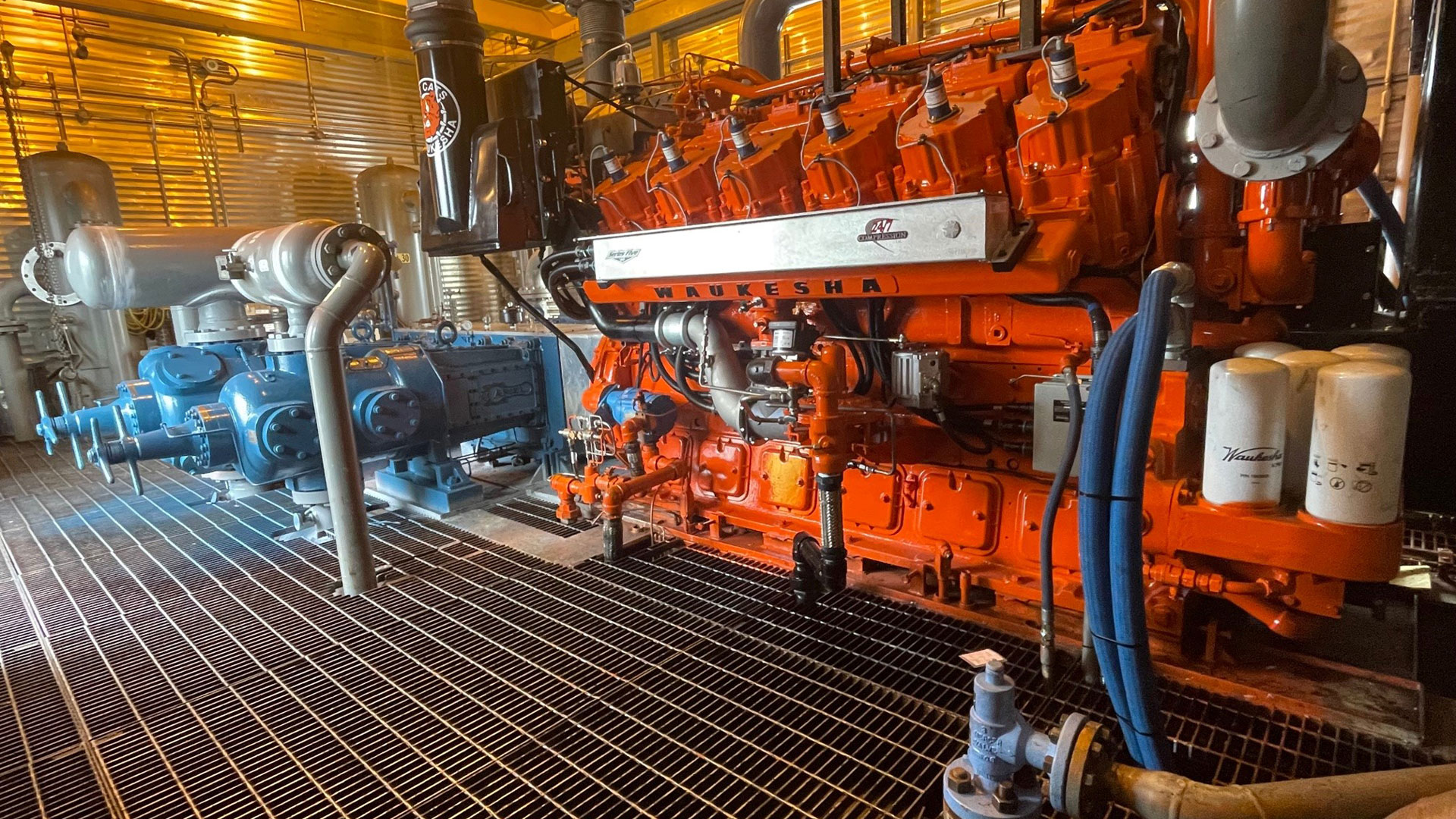

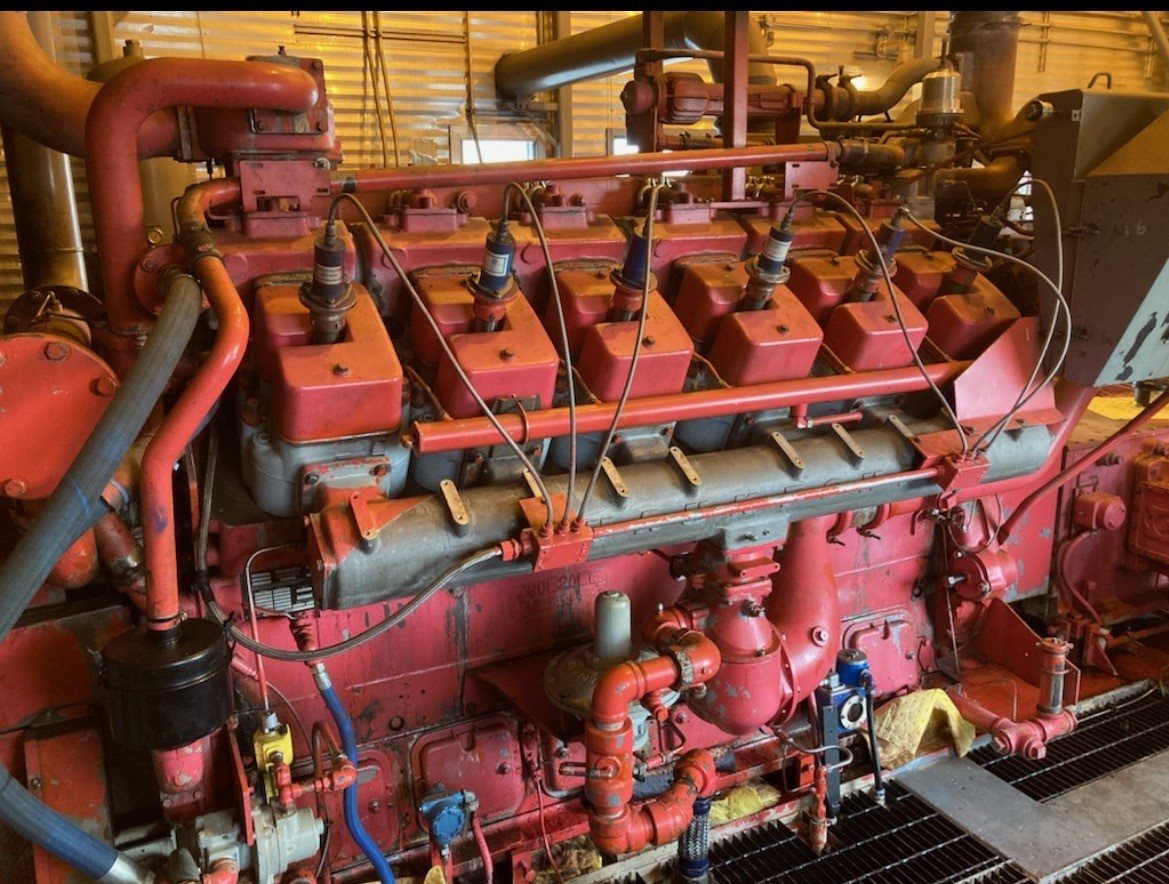

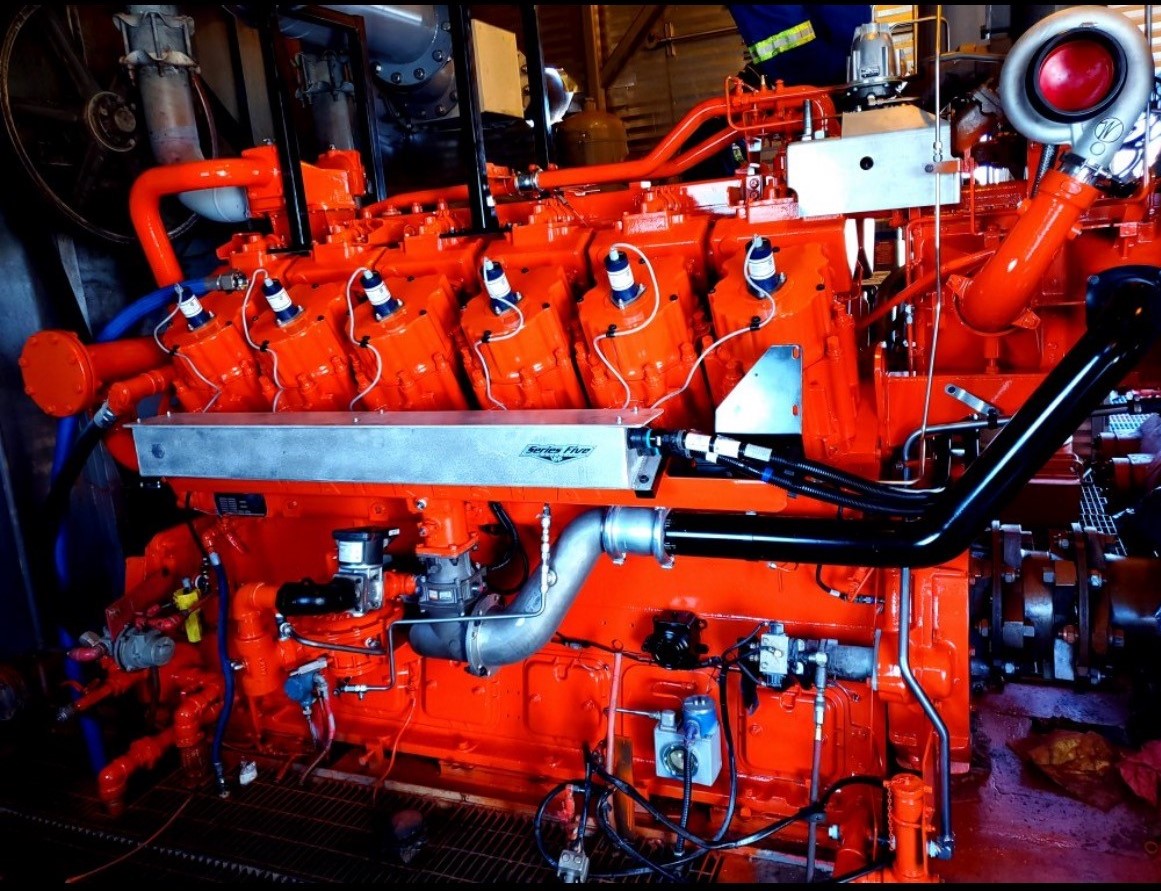

Though eliminating methane emissions isn't possible, at 24/7 Compression, we are committed to providing greener solutions. After extensive job creation, roughly 15,000 person-hours, we're proud to have finished converting 25 Waukesha L7042GL lean burn technology engines to the new Waukesha L7044GSIS5 with catalyst miller cycle technology.

Pre-Conversion

Post-Conversion

With methane abetment and emission reduction being the key focus point on this project, completing this was a great success and will positively impact our environment! Not only does this reduce the carbon footprint, but other benefits include a reduction in tier tax, additional HP, and having robust and reliable equipment.

Notable Emission Reductions

After the engine conversion, we reduced the total CO2e equal to 26,820 tonnes CO2e/year. This is the same as taking 8217 passenger cars off the road, the same as 17,933 homes' electricity use for one year! If this isn't huge, then we don't know what is.

Choose 24/7 Compression Today For Fuel Conversion Needs

We specialize in gas compression equipment and power generation packages. If you'd like to reduce your carbon footprint, contact us! We have locations in Alberta and British Columbia.

So you have a new generator, and you aren't sure if it is ready for a steady workload. Like any engine, generators require preparation before they can be used regularly. Breaking in a generator helps prolong the life of your equipment.

What is Breaking in a Generator?

When you break in a generator engine, you ensure that the pistons and rings in the engine wear grooves into the chamber's walls. Then, allowing oil to lubricate these components every time the generator is running correctly.

In general, it refers to letting your generator run and changing its oil a few times. We do this so that the oil can travel through parts to make them more active and gives the engine a smoother performance. Thus decreasing the possibility of any parts breaking inside the engine.

How to Break in a Generator

1. Start with the manual

The most crucial step is to read the manufacturer's instruction manual. I know everyone says to read the instructions, and most people don't, but this is very important. The owner's manual can provide specific information about your particular generator, like what type of oil it needs, frequency of oil changes, and recommended fuel. Make sure to read this manual. You don't want to do anything that could lead to voiding the warranty.

2. Get the necessary supplies

You'll need to gather a few items to break in the generator. First, make sure you have gasoline; check what type of gasoline the manual has recommended. If there is none, try to get the best quality gasoline, one with the highest octane. The second item will be oil. Again, refer back to the manual for what the manufacturer recommends. Next, you will need oil conditioner; this will help reduce dry starts, which are detrimental to engines. And finally, a funnel to help you pour in the liquids quickly and mess-free.

3. Fill the oil reservoir and run

Next, it is essential to fill your oil reservoir. Before all this, it is a good idea to remove the spark plug and pour the oil conditioner into the spark plug chamber. Now, fill the oil reservoir with the recommended oil. Then add the recommended amount of fuel if the first pull doesn't start your engine. Do not panic. It may need a few tries before getting it running. Once started, let the generator run for one hour with no load. Drain the oil and filter out all metal fragments from the engine when you're done running it.

4. Repeat step 3 a few times

Repeat this a couple more times, and each time pour some oil conditioner before pouring in the oil. After draining the oil for the second time, you can add a 500 watt load during the final run.

You have now successfully broken in your generator! Never neglect regular maintenance. Ensure you are properly maintaining your generator to prolong its life.

Need a New Generator?

At 24/7 Compression, we offer custom natural gas, diesel and propane power generator packages. Our experienced team of professionals can effectively analyze your needs to find the most efficient equipment to execute your project. If you have any questions about generators, contact us today!

Compressing methane (natural gas) is an important step in production and delivery. Learn all about how to safely compress methane gas below.

What is Methane?

Methane is an odourless, colourless and flammable gas that can be produced naturally and synthetically. Methane is the main component of natural gas and is used for heat and electricity around the world. It is also used in chemical reactions to produce other gasses like hydrogen and carbon monoxide. Methane is also a significant contributor to climate change. It is a type of greenhouse gas that plays a factor in the weakening of the ozone layer.

Where do you find Methane?

Methane can be produced through chemical reactions when organic matter decomposes in low-oxygen environments like swamps. As plants die and sink to the bottom of these swamps, bacteria break them down. Thus, wetlands are a large natural contributor to methane gasses.

Methane is also found underground in fossil fuel deposits that have been subjected to high pressure and temperatures over millions of years. Methane is extremely hard to transport since, at normal temperatures, it is in gas form. Usually, Methane is transported by bulk using pipelines. Compressing this natural gas allows it to be used as fuel for vehicles, also considered more environmentally friendly than other types of fuels.

So what is the safest way to transport and compress this gas?

Lower the temperature of the tank to compress the methane gas. When temperatures are near absolute zero, methane gas can turn into liquid form. First, connect a compressor to the tank that is filled with methane gas. This container will also need to be connected to a liquid nitrogen tank with the pipeline. When all the Methane has entered the liquid nitrogen tank, cool the gas in this tank for at least two days. Then, turn on the compressor and let it compress the Methane. Eventually, the Methane will compress and form at the bottom of the tank.

Contact Your Local Compression Experts Today

At 24/7 Compression, we offer compression services and packages for large-scale facilities and smaller projects. We provide superior expertise, knowledge and experience. If you have any questions, please contact us; we're happy to help.