There is a growing production and use of natural gas across North America. While this comes with many advantages, it also poses other threats. The environmental impact is at the top of the list of concerns, which calls for gas compression emission management.

Sources of Gas Compression Emissions in the Industrial Sector

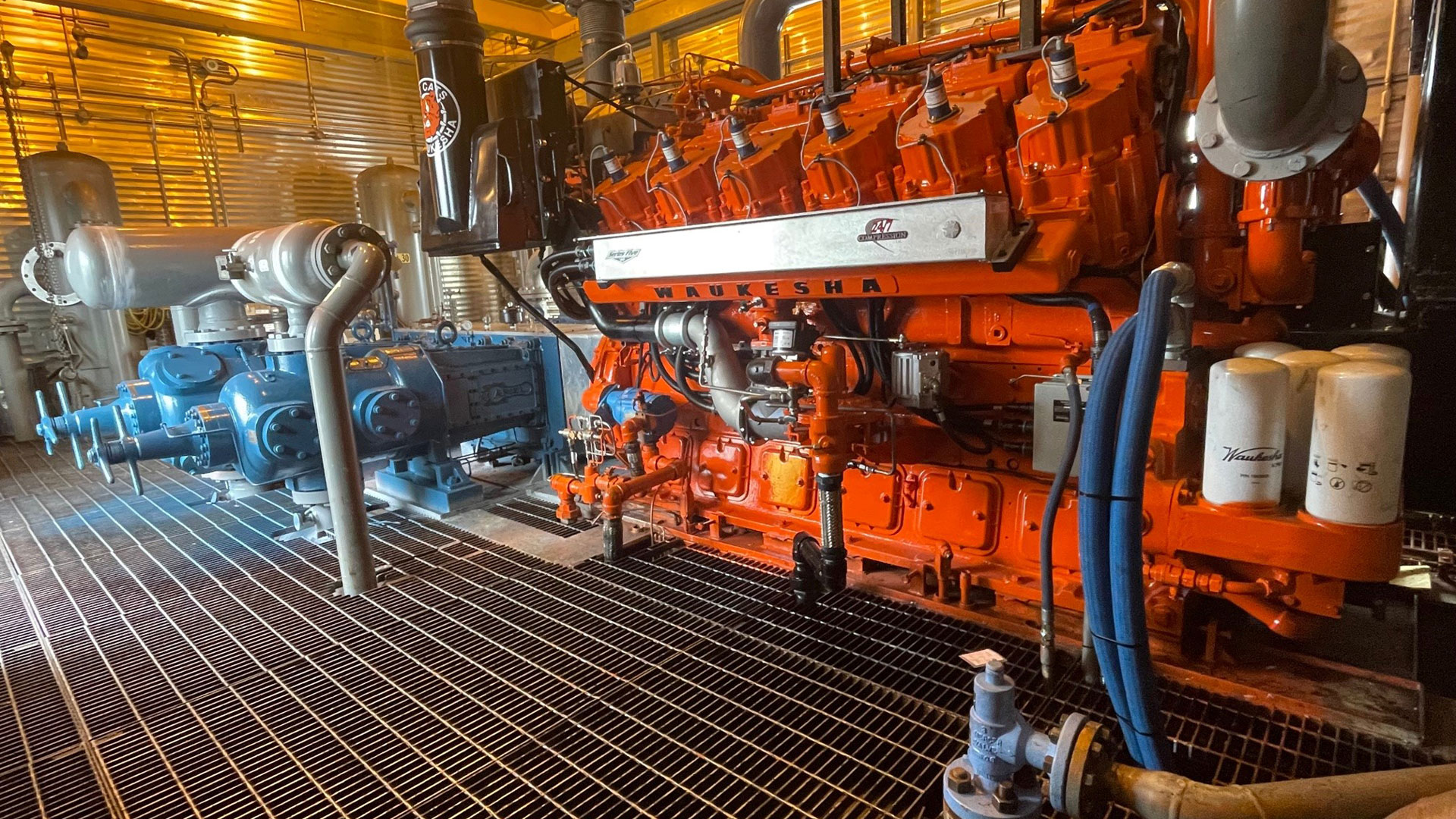

Managing your gas compression starts with understanding your compression system. Notably, centrifugal compressors use wet gas seals or dry gas heals. The seals help prevent methane gas or process gas leakage at the points where the shafts and compressor casings meet.

Compressor stations are an integral part of the natural gas pipeline network that helps to reduce pressure and maintain flow in transporting natural gas from individual well sites. As natural gas moves through the pipeline, it is slowed by distance, friction and elevation differences. Compressor stations help these issues be resolved strategically placed within gathering or transportation pipelines so they can continue on their journey to market.

Over the last few years, there has been an increase in demand for clean energy sources. Natural gas power generation is a good choice for many industries looking for an efficient primary or backup source of power that is more environmentally friendly than traditional fuels. But what are the main advantages of this type of power generation, and is it a suitable solution for your industry?

Processing natural gas separates all the various hydrocarbons and liquids from it to produce pipeline-quality dry natural gas. On the other hand, natural gas liquids are used in various industries for producing fuel and even plastics.

At 24/7 Compression, we offer a wide variety of gas compression and processing service packages for small- and large-scale facilities. Learn more about our company and how we can help.

Industrial power generators are often used in factories, schools, hospitals, and other institutions for their need for constant power. Apart from the obvious benefits of an uninterrupted power supply, they also provide a sense of safety and security. Moreover, besides the fact that industrial power generators have a lot to offer in terms of function and safety, they also provide cost-efficiency.

The process of choosing a power generation system is not an easy one. There are many factors to consider to make the right decision compliant with your business goals. The first step of that process would be to research and compare the different opportunities on the market. This may take a lot of time and effort, especially if you are unsure what exactly to look for when comparing different power generation packages. However, at 24/7 compression, we value your time, and we want to help you make an informed decision that will pay off in the future.

Greenhouse gas (GHG) is a gas in the atmosphere that absorbs and emits radiation within the thermal infrared range. This process by which greenhouse gases trap heat in an atmospheric layer is also called the greenhouse effect or sometimes simply greenhouse. Greenhouse gases contribute to the warming of our atmosphere because they absorb the energy from sunlight and warm-up, rather like a greenhouse does.