Can Sliding Valve Compressors Be Retrofitted in Natural Gas Applications?

In Canada’s natural gas sector, compressors aid in gathering, processing, and transmission. As operators aim to improve efficiency and reduce emissions, some have considered retrofitting older compressors with sliding valve mechanisms. While common in some compressors, slide valves are not standard in all installations, raising the question: can they be retrofitted?

What Is a Sliding Valve and Where Is It Used, Practically?

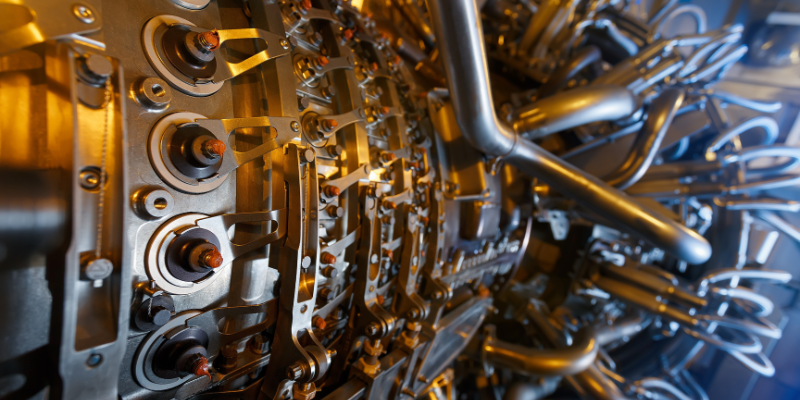

A sliding valve is a mechanical device built into many oil-flooded rotary screw compressors, allowing the internal compression volume (Vi) to be adjusted without changing speed or bypassing gas. This improves turndown and part-load efficiency, especially in facilities with fluctuating flow rates.

In Canada, large screw compressors used in gas gathering often include slide valves from the outset. For units that don’t, retrofitting typically involves replacing the entire rotor housing or compressor insert. This is rarely done in the field, as it requires tight machining tolerances and OEM-supplied components. Manufacturers like Dresser-Rand (now Siemens Energy) or Howden may offer upgrade paths, but retrofits are typically cost-effective only when integrated with broader overhaul work.

In contrast, reciprocating compressors (commonly used in gas plants and midstream systems) don’t use sliding valves. Instead, capacity is controlled with suction valve unloaders or clearance pockets, such as Ariel’s Variable Volume Clearance Pockets (VVCP). These pockets can often be retrofitted onto existing cylinders to adjust volume and reduce flow without venting gas. Retrofitting a VVCP is relatively straightforward and supported by most OEMs, provided the frame has the necessary ports and clearance.

Mechanical and Regulatory Feasibility

In Alberta and other provinces, retrofitting pressure components requires careful compliance with the Alberta Boilers Safety Association (ABSA) and CSA Z662 standards. ABSA treats a sliding valve retrofit or clearance pocket addition as an alteration if it affects the pressure boundary or system control. Such modifications may require a revised Canadian Registration Number (CRN) and documentation prepared by a professional engineer.

CSA Z662, Canada’s pipeline and facility code, mandates that compressor stations maintain safe and reliable operations under changing conditions. Retrofitted components must be evaluated to ensure they don’t affect system integrity, overpressure protection, or compressor performance. Engineers must verify that pressure relief devices remain adequately sized and that modifications do not violate design tolerances.

Emissions and Methane Reduction Benefits

Canada’s federal methane regulations, led by Environment and Climate Change Canada (ECCC), require upstream oil and gas producers to significantly reduce methane emissions. Compressors without proper turndown often vent gas during idle cycles or rely on high-bleed pneumatic controllers.

By enabling better part-load control, sliding valves and VVCPs reduce the need to vent or recycle gas. In reciprocating compressors, modern pockets can replace continuous bleed devices, helping operators meet methane limits while lowering fuel consumption. These retrofits also contribute to compliance under Alberta’s Directive 060, which aligns with federal methane rules.

How Common Are These Retrofits?

Retrofitting clearance pockets into reciprocating compressors is fairly routine, especially when adapting equipment to declining well pressures or lower throughput. Operators can often install these upgrades during scheduled overhauls with support from OEMs like Ariel or GE’s Nuovo Pignone.

However, slide valve retrofits into rotary screw compressors are less common. Most slide valves are integral to the casing and not easily added post-manufacture. In such cases, operators may instead use Variable Frequency Drives (VFDs) or bypass systems to achieve turndown—though these don’t offer the same efficiency benefits.

Find The Compression Equipment You Need Today

Retrofitting sliding valve mechanisms or clearance-control devices can be technically feasible and beneficial. While reciprocating compressors support aftermarket capacity upgrades, retrofitting slide valves into screw compressors is often limited by design constraints and cost.

Operators needing such upgrades should contact 24/7 Compression for gas compression solutions that meet your demands. We offer servicing, rentals and new equipment for North America’s Natural Gas Industry.