Processing natural gas separates all the various hydrocarbons and liquids from it to produce pipeline-quality dry natural gas. On the other hand, natural gas liquids are used in various industries for producing fuel and even plastics.

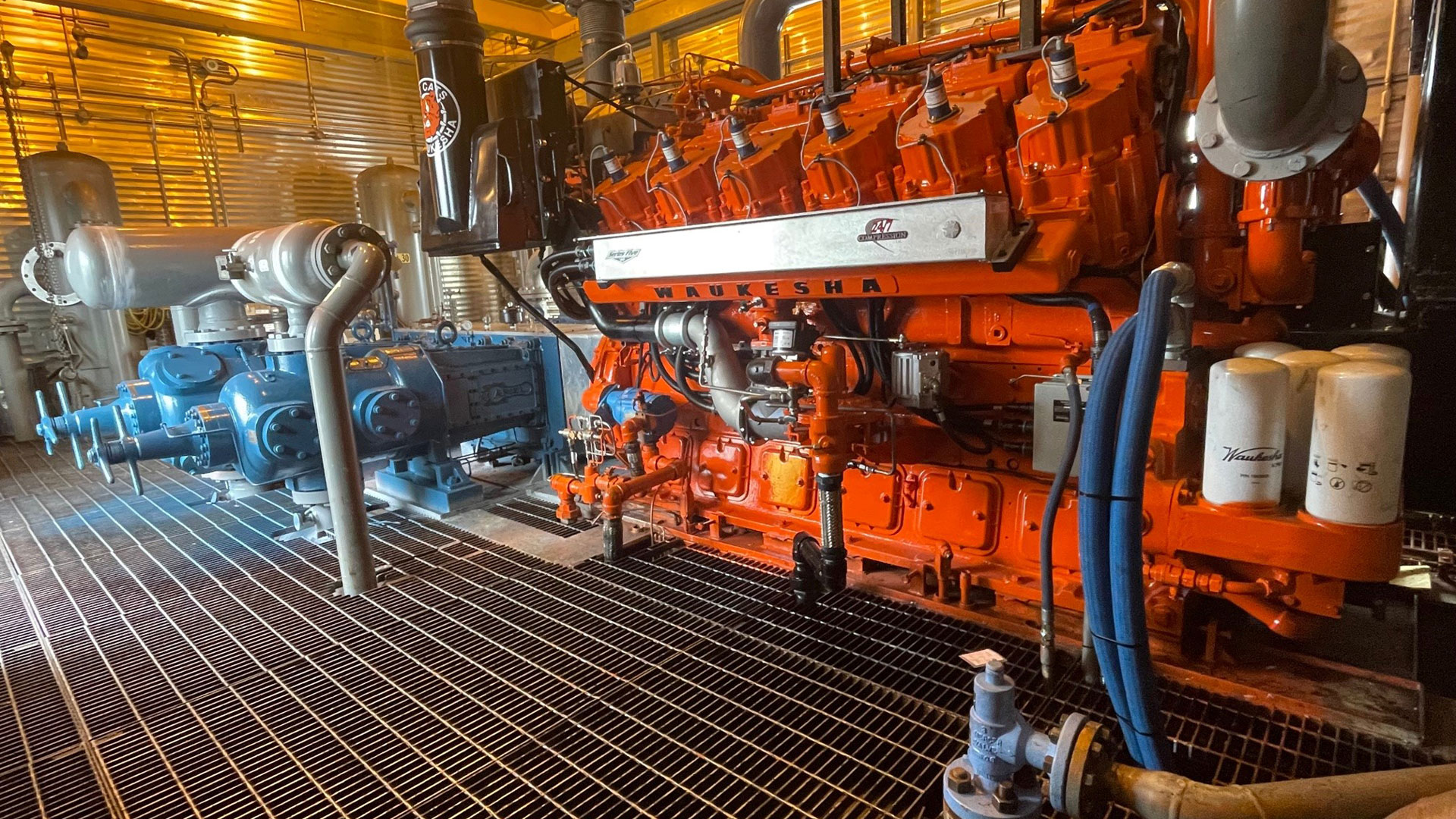

At 24/7 Compression, we offer a wide variety of gas compression and processing service packages for small- and large-scale facilities. Learn more about our company and how we can help.

Industrial power generators are often used in factories, schools, hospitals, and other institutions for their need for constant power. Apart from the obvious benefits of an uninterrupted power supply, they also provide a sense of safety and security. Moreover, besides the fact that industrial power generators have a lot to offer in terms of function and safety, they also provide cost-efficiency.

The process of choosing a power generation system is not an easy one. There are many factors to consider to make the right decision compliant with your business goals. The first step of that process would be to research and compare the different opportunities on the market. This may take a lot of time and effort, especially if you are unsure what exactly to look for when comparing different power generation packages. However, at 24/7 compression, we value your time, and we want to help you make an informed decision that will pay off in the future.

Greenhouse gas (GHG) is a gas in the atmosphere that absorbs and emits radiation within the thermal infrared range. This process by which greenhouse gases trap heat in an atmospheric layer is also called the greenhouse effect or sometimes simply greenhouse. Greenhouse gases contribute to the warming of our atmosphere because they absorb the energy from sunlight and warm-up, rather like a greenhouse does.

Compressing methane (natural gas) is an important step in production and delivery. Learn all about how to safely compress methane gas below.

What is Methane?

Methane is an odourless, colourless and flammable gas that can be produced naturally and synthetically. Methane is the main component of natural gas and is used for heat and electricity around the world. It is also used in chemical reactions to produce other gasses like hydrogen and carbon monoxide. Methane is also a significant contributor to climate change. It is a type of greenhouse gas that plays a factor in the weakening of the ozone layer.

As the world tries to make its way to greener energy use, many countries are now using natural gas to generate electricity more cleanly than other fossil fuels. Fortunately for us, Canada is one of the largest producers of natural gas in North America. The country has significant reserves, primarily located in Alberta, British Columbia, and Saskatchewan. Also, according to SoCalGas, 92% of the natural gas is delivered as energy after transmission, which means that only 8% is energy lost. As a major natural gas producer, that means Canada can jump on this cleaner energy train.